| Tipos de produtos usados | Auxílio de Fluxo , Pontos de Transferência , Canhões de Ar , Estrutura do Chute |

|---|---|

| [unset] | MartinPLUS® Instalação e Manutenção |

| Indústria | Usinas Termelétricas |

| cliente | Hennepin Power Station, Dynegy Midwest Generation Hennepin, Illinois |

Problema

During the plant’s summer outage, an independent contractor designed and installed new chutes to feed the coal mills. But at start-up, material clogged in these new chutes and closed off the flow of coal into the boilers, causing the plant to shut down. The plant needed an emergency-response “quick fix” to return to production and an engineered solution for long-term correction.

Solução

Martin Engineering responded the next business day to get the plant on-line. Crews from MartinPLUS® Installation Service replaced the abrasion-resistant steel liners in the chutes with low-friction UHMW polyethylene. In one shift, MartinPLUS® Installation field crews had two of three chutes converted, allowing the plant to return to operation.

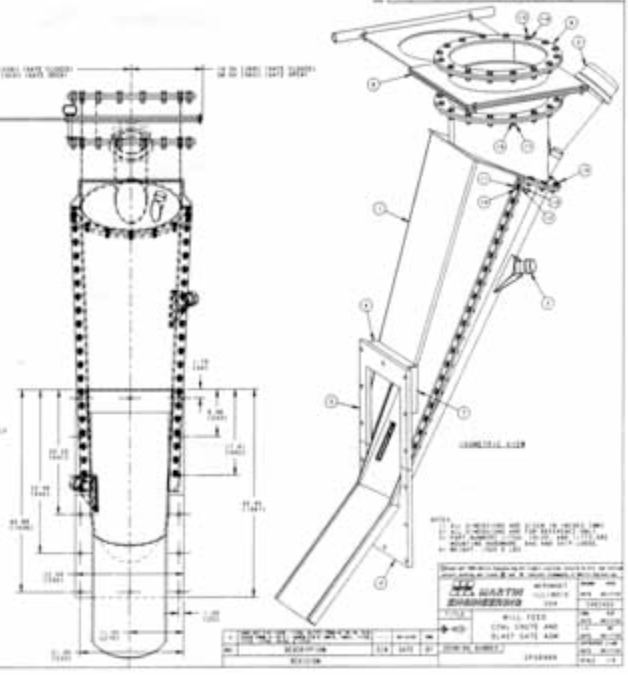

To provide a more reliable arrangement, Martin Engineering designed new chutes using a steeper approach to the mill inlet and incorporating a stainless steel half-trough pan to promote flow. The design also called for installation of Martin® Air Cannons one on each chute to discharge along the back of the chute and blow out potential material bridges.

After fabrication of the components, Martin Engineering delivered the chute section to the plant to await a suitable outage for installation. When the plant went down for a scheduled outage, installation crews from MartinPLUS® Installation Services worked around the clock on 12-hour shifts to complete the installation. The plant returned to operation in 36 hours on schedule.

Resultados

Coal flow has been maintained without plant shutdowns. “We do appreciate the responsiveness of Martin Engineering and their willingness to schedule and reschedule to meet our needs.”

Resolvemos o seu problema!

Com mais de 70 anos de experiência resolvendo problemas em todo mundo com os profisisonais mais experientes e educados em nossas equipes, podemos assegurar-lhe que ficaremos perto o suficiente para saber o que precisa ser feito em seguida e resolver o seu problema.

Deixe-nos lhe mostrar a solução.