| Produtos usados | Janelas de Inspeção , Raspador QC1™ XHD |

|---|---|

| Tipos de produtos usados | Raspadores de Correia , Soluções em Segurança , Acessórios para Segurança , Raspadores Primários , Raspadores Secundários |

| [unset] | MartinPLUS® Instalação e Manutenção |

| Indústria | Usinas Termelétricas |

| cliente | Consumers Energy, D.E. Karn Plant Essexville, Michigan |

Problem

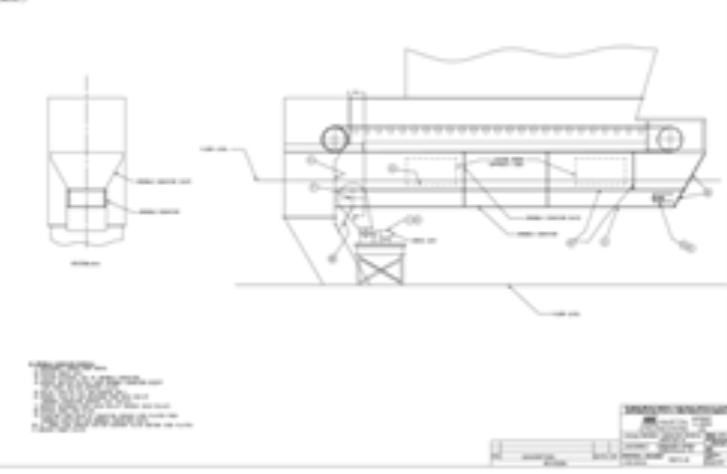

The drag chain conveyor under a slow moving 60-inch (1524 mm) feed conveyor was inoperable. The Engineered Projects Group of Martin Engineering was called in to engineer the existing system’s tear-out and design a new dribble chute with the installation of Martin® Belt Cleaners.

Solution

MartinPLUS® Service technicians prepared and sent detailed drawings with a step-by-step procedure for removal of the drag chain conveyor. Following removal and then construction of a new dribble chute by a local contractor, Martin Engineering's regional MartinPLUS® Service technician installed a new belt cleaner system composed of a Martin® QC1™ Cleaner XHD and Martin® Secondary Cleaner with Martin® Inspection Doors.

Results

The new belt cleaning system works in combination with the new dribble chute to remove carryback and return material to the main material stream.

Resolvemos o seu problema!

Com mais de 70 anos de experiência resolvendo problemas em todo mundo com os profisisonais mais experientes e educados em nossas equipes, podemos assegurar-lhe que ficaremos perto o suficiente para saber o que precisa ser feito em seguida e resolver o seu problema.

Deixe-nos lhe mostrar a solução.